In accordance with the personal data protection law implemented by the European Union, we are committed to protecting your personal data and giving you control over it. By clicking "Accept All", you allow us to place cookies to enhance your experience on this website, assist us in analyzing website performance and usage, and enable us to serve related marketing content. You can manage your cookie settings below. Clicking "Confirm" means you agree with the current settings.

Product Overview

Bicycles

Anvil has many years of experience in OEM for well-known bicycle brands.

Product Display

-

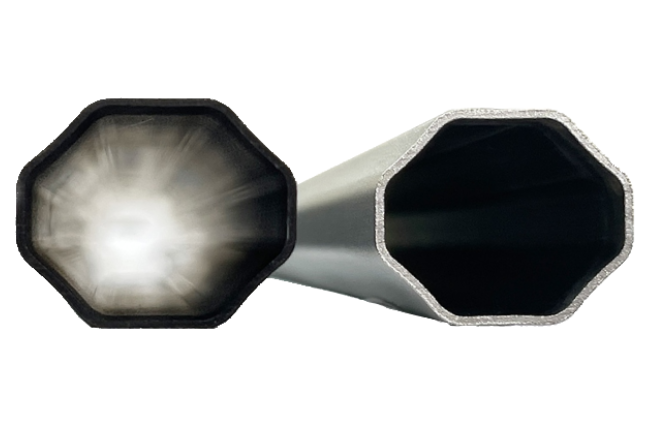

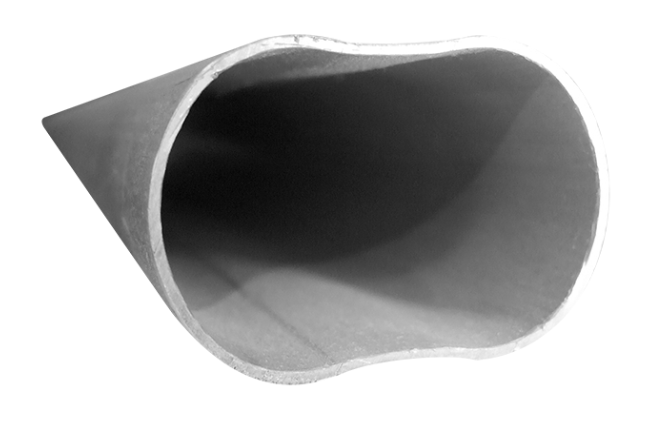

Bicycle Front Fork Steerer Tube

The steerer tube is located in the upper half of the fork and is responsible for connecting the frame and the handlebars. It works in conjunction with the fork's inner tube to support the entire fork structure. The material and design of the steerer tube are important factors affecting the riding experience. We provide customized steerer tube solutions, manufactured according to customer specifications, to fully meet the needs of specific bicycle applications.

◆Product Information◆

Specification (big end diameter): 39mm~42.6mm

Specification (outer diameter of the small end): 25.4mm~28.6mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: bicycle components

Advantages: suction tube processing and forming, higher strength

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: the blank has passed the ASTM tensile test -

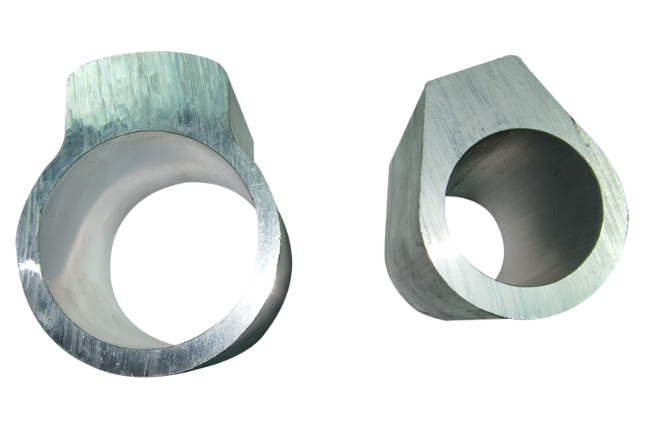

Bicycle Front Fork Inner Tube

The inner tubes are paired with the steerer tube to connect the wheel and are used to secure the front wheel. Anvil offers high-quality bicycle front fork inner tubes that can meet various application needs by adjusting the inner diameters and material of the tube ends. The inner tubes maintain smooth fork movement, offer excellent shock absorption, and provide a more stable riding experience for the cyclist.

◆Product Information◆

Specification (inner diameter): 26mm~33mm

Specification (outer diameter): 32mm~38mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: bicycle components

Advantages: straight front fork tube, TP section front fork tube (professional thick and thin tube)

Metal appearance surface treatment: hard anodized treatment

Stress test: the blank has passed the ASTM tensile test -

-

-

Downhill Bike Handles

Designed for off-road mountain biking with significant elevation changes, these handles offer greater width and rise to provide better control and stability on steep descents and rugged terrain. Made of high-quality aluminum alloy, they can withstand extreme vibrations and stress. Whether your customers are professional off-road bikers, high-performance handle-requiring bike brands, or shared bicycle service providers, we offer customized solutions.

◆Product Information◆

Specification (intermediate outer diameter): 31.8mm / 35mm

Specification (handle outer diameter): 22.2mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: bicycle handle

Advantages: Recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: rough embryos and finished products have passed the ISO4210 fatigue test

R number (lifting amount): R5/R15/R20/R30/R60/R75

Others: can do blank processing and finished product processing -

Flat Bike Handles

Designed for urban cycling and leisurely rides, these handles are typically narrower, allowing cyclists to easily navigate through city traffic. Made of high-quality aluminum alloy, they are both lightweight and sturdy. Ideal for those seeking comfortable grips and simple control, such as urban leisure bike brands.

◆Product Information◆

Specification (intermediate outer diameter): 31.8mm / 35mm

Specification (handle outer diameter): 22.2mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: bicycle handle

Advantages: Recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: rough embryos and finished products have passed the ISO4210 fatigue test

R number (lifting amount): R5/R15/R20/R30/R60/R75

Others: can do blank processing and finished product processing -

Road Bike Aluminum-Carbon Handlebars

For professional road bike brands seeking ultimate lightweight and performance, we offer aluminum-carbon handlebars. These handles combine the lightweight advantages of aluminum alloy with the rigidity of carbon fiber, offering the best compromise. They are well-designed to provide excellent control at high speeds. Not only do our aluminum-carbon handlebars improve bike performance, but they also offer high durability to meet professional cycling needs.

◆Product Information◆

Specification (intermediate outer diameter): 31.8mm / 35mm

Specification (handle outer diameter): 22.2mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: Aluminum Carbon Fiber

Tolerance range: According to the requirements of the drawing

Application: bicycle handle

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: sand blasting, anodic treatment

Stress test: rough embryos and finished products have passed the ISO4210 fatigue test

R number (lifting amount): R5/R15/R20/R30/R60/R75

Others: can do blank processing and finished product processing

Features: Made using one-piece molding technology, offering both ultra-lightweight and high rigidity

-

Wide-Angle Road Bike Drop Bars (Flat Tube Series)

Mainly applicable to road bicycles, especially for long-distance cycling events. Their unique curvature provides multiple grip options, adapting to different riding styles and terrains, making them an ideal choice for long-distance cycling trips and races. These handles are very suitable for high-end bike brands, bike parts retailers, and brands looking to offer high-quality bike parts. They are usually the first choice for riders and brands seeking ultimate performance.

◆Product Information◆

Specification (intermediate outer diameter): 31.8mm / 35mm

Specification (handlebar outer diameter): 24mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: bicycle handle

Advantages: Recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: rough embryos and finished products have passed the ISO4210 fatigue test

Bending angle: according to the requirements of the drawing

Others: can do blank processing and finished product processing -

BMX Bike Handles

Bicycle Motocross Handlebars

Designed for extreme sports, suitable for BMX races, Freestyle BMX, and other challenging bike sports. They are robust and durable, capable of withstanding a great deal of impact and pressure. These handles are ideal for niche bike brands, extreme sports gear brands, and suppliers looking for sturdy, high-performance handles. They are usually the first choice for extreme sports enthusiasts and professional athletes.

◆Product Information◆

Specification (intermediate outer diameter): 31.8mm / 35mm

Specification (handlebar outer diameter): 22.2mm

▶Only the more common sizes are listed, and the actual adjustments are made according to the drawing.

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: bicycle handle

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: anodized

Color: all customized

Stress test: rough embryos and finished products have passed the ISO4210 fatigue test

Bending angle: according to the requirements of the drawing

Others: can do blank processing and finished product processing

Seat posts

◆Product Information◆

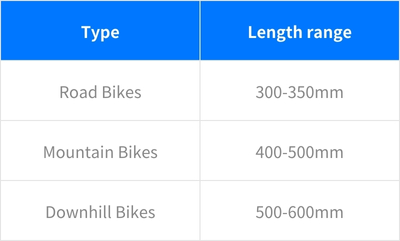

Common bicycle seat post inner/outer diameter specifications:

Common seat post lengths:

▶These are just some common sizes, adjustments should be based on design drawings.

Material: 7050 / 6-series Aluminum Alloy

Application: Bicycle components

Metal Surface Finish: Anodizing, Plating, Painting, Brushing

Strength Requirements: According to ISO 4210-2:2015 standards, the static tensile strength of seat posts should be at least 250 N/mm²

Medical Equipment

Reliable wheelchair suppliers have long-term collaborations with Anvil,manufacturing wheelchairs and electric mobility scooter handlebars, along with other medical assistive devices for overseas sales.

Moreover, our products are corrosion-resistant, meeting the cleanliness and disinfection requirements of medical environments.

We understand the uniqueness of each different project, thus offering OEM/ODM solutions.

Product Display

-

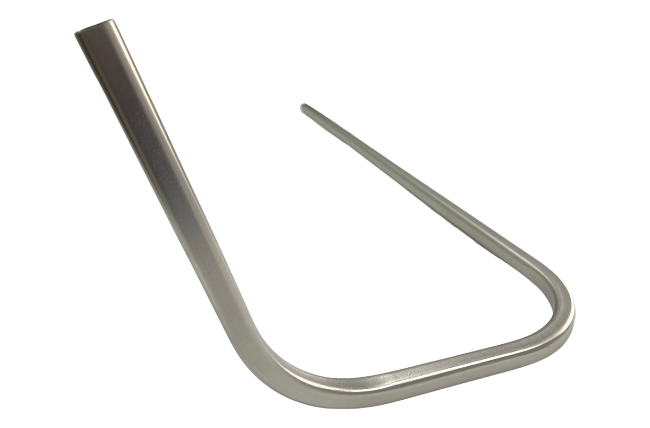

Wheelchair Grips

A crucial component of wheelchairs, the grips provide overall directional control. The metal parts of the grips provided by Anvil are made of aluminum alloy, offering sufficient strength and durability.

◆Product Information◆

Specification (outer diameter): 16mm~28mm

▶Specifications are customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Medical Device Components

Advantages: light and durable

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: ASTM Tensile Test

Bending angle: according to the requirements of the drawing -

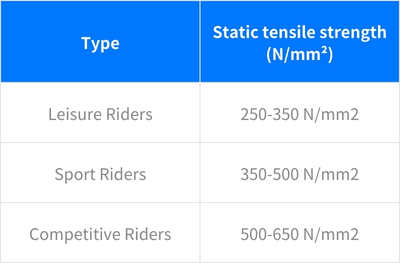

Wheelchair Frame

The primary function of the wheelchair frame is to support the seat, axle, and other parts while providing a stable platform for the user to sit and move.

◆Product Information◆

Specification (outer diameter): 16mm~28mm

▶Specifications are customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Medical Device Components

Advantages: light and durable

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: ASTM Tensile Test

Bending angle: according to the requirements of the drawing -

Wheelchair Push Handles

The push handles have a thread-cutting groove at the tube end, complementing other components, and are also part of the frame located at the back of the wheelchair. They are used by caregivers or assistants for pushing and maneuvering the wheelchair. The design of the push handles allows caregivers to easily control the wheelchair’s movement, offering better mobility freedom and ease of operation for caregivers.

◆Product Information◆

Specification (outer diameter): 16mm~28mm

▶Specifications are customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Medical Device Components

Advantages: light and durable

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: ASTM Tensile Test

Bending angle: according to the requirements of the drawing

Electric Mobility Scooter Handlebars

◆Product Information◆

Specification (outer diameter): 22.2mm

▶Specifications are customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: electric motorcycle handle

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: anodized

Color: all customized

Stress test: blanks and finished products can be subjected to fatigue test

Bending angle: according to the requirements of the drawing

Others: can do blank processing and finished product processing

Motorcycles

The motorcycle industry has a huge market in Taiwan and is also an important mode of transportation in countries of Southeast Asia.

The Taiwanese market has various types of two-wheelers, such as motorcycles and electric scooters.

They are used for short-distance transportation, delivery, and personal outings, thus prioritizing convenience and cost-effectiveness.

We offer safer, more reliable, and quality-stable customized options for motorcycle manufacturers, parts suppliers, and repair service providers in a B2B capacity.

Product Display

-

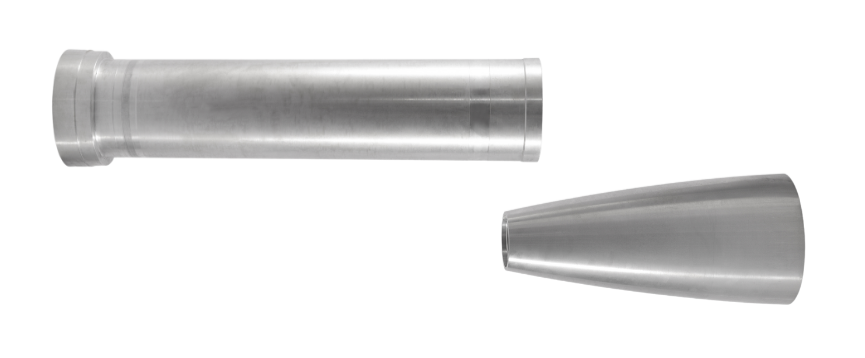

Motorcycle Inner/

Outer Shock Tubes

Inner/outer shock tubes are a part of the motorcycle's front fork assembly, used for connecting the front wheel and the frame. The suspension forks manufactured by Anvil are made of aluminum alloy and have adequate strength and rigidity to withstand the weight of the front wheel and road pressures. Their primary function is to support the front wheel while also providing motion and shock absorption in the motorcycle's suspension system.

◆Product Information◆

Specification (inner diameter): Customized according to the drawings

Specification (outer diameter): Customized according to the drawings

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Locomotive components

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: electroplating, painting, oxidation, baking, anodizing

Stress test: ASTM Tensile Test

Color: all customized -

Motorcycle Handles / Electric Scooter Handlebars

The handlebars for motorcycles and electric scooters allow riders to easily control the direction of the vehicle. They come in different shapes and sizes to fit various types of motorcycles, with some even having adjustable heights to accommodate riders of different heights. Anvil provides end-to-end customization for these handlebars.

◆Product Information◆

Specification (intermediate outer diameter): 28.6mm

Specification (handlebar outer diameter): 22.2mm

▶Specifications are customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6061 / 6066 / 2014 aluminum alloy

▶Only the more common materials are listed, and the actual choice is based on the needs.

Tolerance range: According to the requirements of the drawing

Application: motorcycle handle

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: anodized

Color: all customized

Stress test: blanks and finished products can be subjected to fatigue test

Bending angle: according to the requirements of the drawing

Others: can do blank processing and finished product processing

Automobiles

The automotive industry is vital globally.

To aggressively expand in the automotive market, the company is actively undergoing educational training for IATF16949:2016, the global quality management system for the automotive industry.

Product Display

-

Tie Rods

Tie rods are an indispensable part of the control system that convey the driver’s commands to the wheels, enabling smooth steering. Our high-quality tie rod designs ensure excellent control and safety, suitable for various vehicle applications. Whether you are a car manufacturer, parts supplier, repair service provider, or auto accessories dealer, we offer solutions tailored to your needs to enhance vehicle performance.

◆Product Information◆

Specification (length): Customized according to the drawings

Specification (width): Customized according to the drawings

Specification (thickness): Customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Auto Parts

Advantages: Can recommend and discuss according to your needs, and customize suitable products

Metal appearance surface treatment: electroplating, spray painting, baking varnish, anodic treatment

Stress test: Stress Test

Color: all customized

Bending radian: according to the requirements of the drawing -

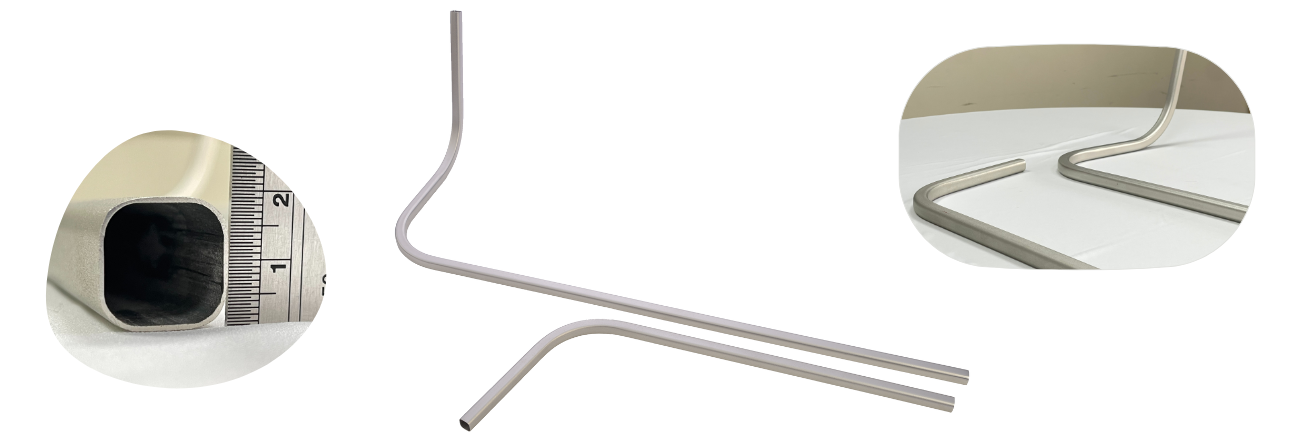

Roof Racks

Car roof racks are accessories installed on the top of the vehicle to carry extra cargo like bicycles and luggage. Our universal car roof racks are made of aluminum alloy, providing a more stable, safe, and lightweight option. Whether you are an auto accessories supplier or a vehicle modification provider, our solutions will help you improve the quality of the finished product to meet customer demands.

◆Product Information◆

Specification (length): Customized according to the drawings

Specification (width): Customized according to the drawings

Specification (thickness): Customized according to the drawings

Weight (g): According to the drawing standard

Length: adjust according to your needs

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Auto parts, installed on the roof to install roof luggage, roof aluminum frame (luggage rack), roof tent, etc.

Metal appearance surface treatment: polishing, baking paint, anodic treatment

Stress test: ASTM Tensile Test

Color: all customized

Bending radian: according to the requirements of the drawing

Sports Equipment

Product Display

-

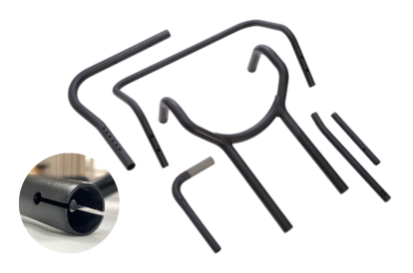

Aluminum Softball and Self-Defense Bat

We offer high-quality aluminum softball bats suitable for various applications, including baseball games, team training, sports equipment sales, and self-defense. The bats are made of sturdy, lightweight aluminum alloy, providing excellent durability and performance. Whether you are a sports equipment store owner, a team coach, or a sports equipment supplier, we can offer products that meet your needs, helping you provide the highest quality equipment to your customers.

◆Product Information◆

Specification:21-34inch

▶If there are other requirements, it can be customized

Weight (g): According to the drawing standard

Material: 7050 /6061 / 6066 / 7068 aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Sports Equipment

Advantages: the weight can be within ±10g

Metal appearance surface treatment: sandblasting, baking paint, anodic treatment

Stress test: ASTM Tensile Test

Color: all customized

Features: Lighter and more durable than wooden baseball bats, designed to enhance swing speed and hitting power, with better weight and balance performance. -

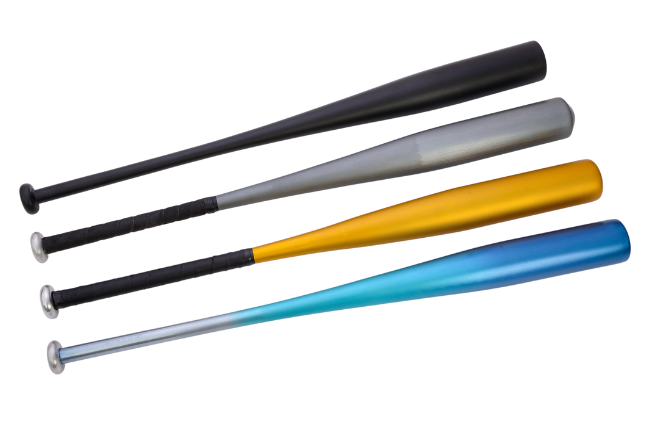

Solid Wood Hardball Bat

Wooden baseball bats are made of solid wood, usually manufactured from maple, white birch, and yellow birch. They come in different styles and offer a classic sound feeling when hitting a baseball. Wooden baseball bats require higher skill to use and are less durable compared to aluminum alloy or composite material bats, but they are still used by professional players due to regulations. The wooden bats come in different sizes, and we offer you customized options.

◆Product Information◆

Specification:21-34inch

▶If there are other requirements, it can be customized

Weight (g): According to the drawing standard

Material: Ash, Maple, Birch

▶If you have other material requirements, you can discuss

Tolerance range: According to the requirements of the drawing

Application: Sports Equipment

Advantages: Customized embossed LOGO, light and durable

Surface treatment: painting, waxing, sanding

Color: all customized

Others: Compared with aluminum alloy baseball bats, wooden baseball bats are more flexible and feel, which can provide better hitting feel and control.

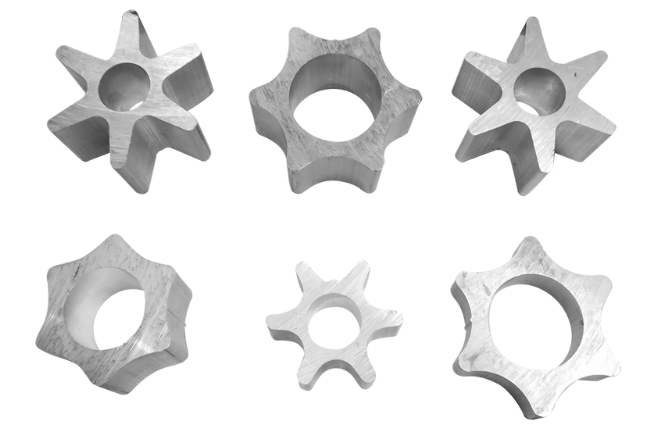

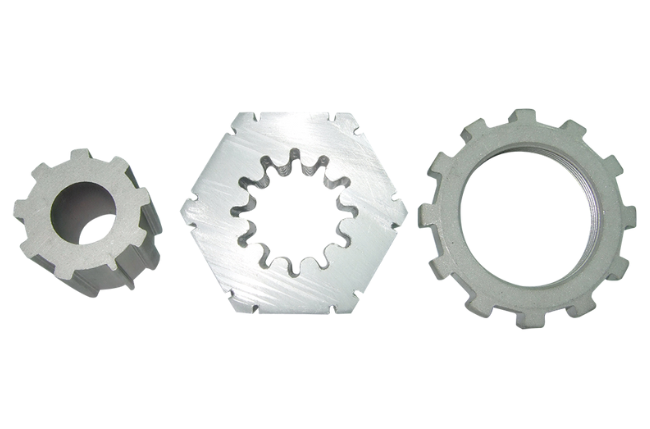

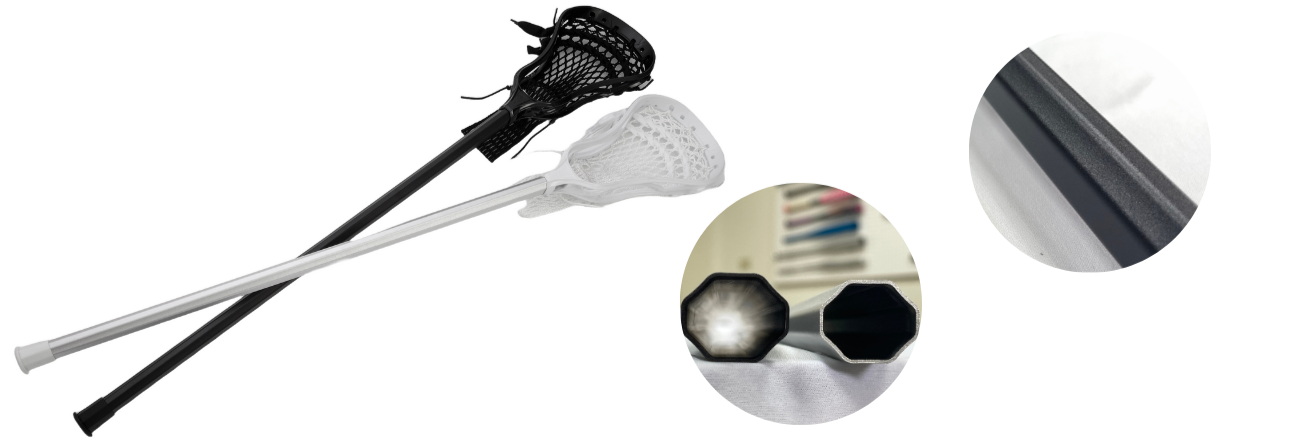

Lacrosse Shafts

◆Product Information◆

Specification:Customized according to the drawings

Dimensions (grip): Customized according to the drawings

Dimensions (shaft head): Customized according to the drawings

Weight (g): According to the drawing standard

Handle material: 7050 / 6 series aluminum alloy

Handle end: traditional rubber end cap

Shaft head: PP polypropylene

Tolerance range: According to the requirements of the drawing

Application: Sports Equipment

Metal appearance surface treatment: sand blasting, anodic treatment

Color: all customized

Stress test: Stress Test

Others: octagonal tubes can be ordered separately, or finished products can be purchased directly.

Defense and Aerospace

Aviation demands a high level of professionalism and safety,requiring sturdy yet lightweight materials and components to reduce fuel consumption and ensure flight reliability.

Whether you are an aviation manufacturer, aviation supplier, or an aerospace maintenance facility, you can contact us to discuss details.

Commercial Airplane Seat Mounting Brackets

◆Product Information◆

Specification (length): Customized according to the drawings

Specification (width): Customized according to the drawings

Specification (thickness): Customized according to the drawings

Weight (g): According to the drawing standard

Length: According to the drawing standard

Material: 7050 / 6 series aluminum alloy

Tolerance range: According to the requirements of the drawing

Application: Aerospace Seat Components

Advantages: light and durable

Metal appearance surface treatment: sandblasting, baking paint, anodic treatment

Color: all customized

Bending radian: according to the requirements of the drawing

Outdoor Gear

Outdoor equipment needs to be sturdy and durable to cope with various extreme conditions and challenges.

If you are an outdoor equipment manufacturer, supplier, or wholesaler, Anvil offers you key solutions.

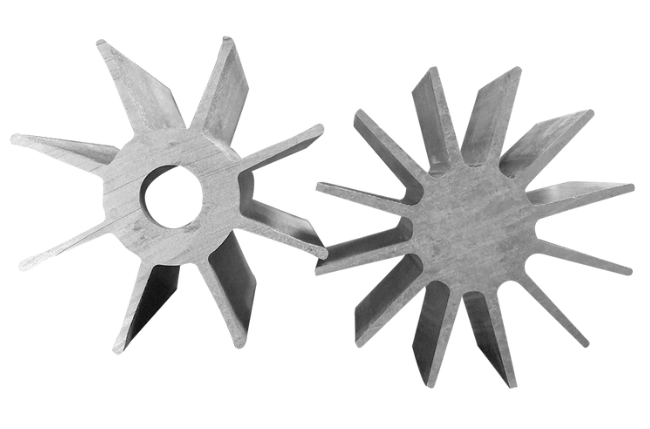

Camping Tent Poles/Aluminum Frames

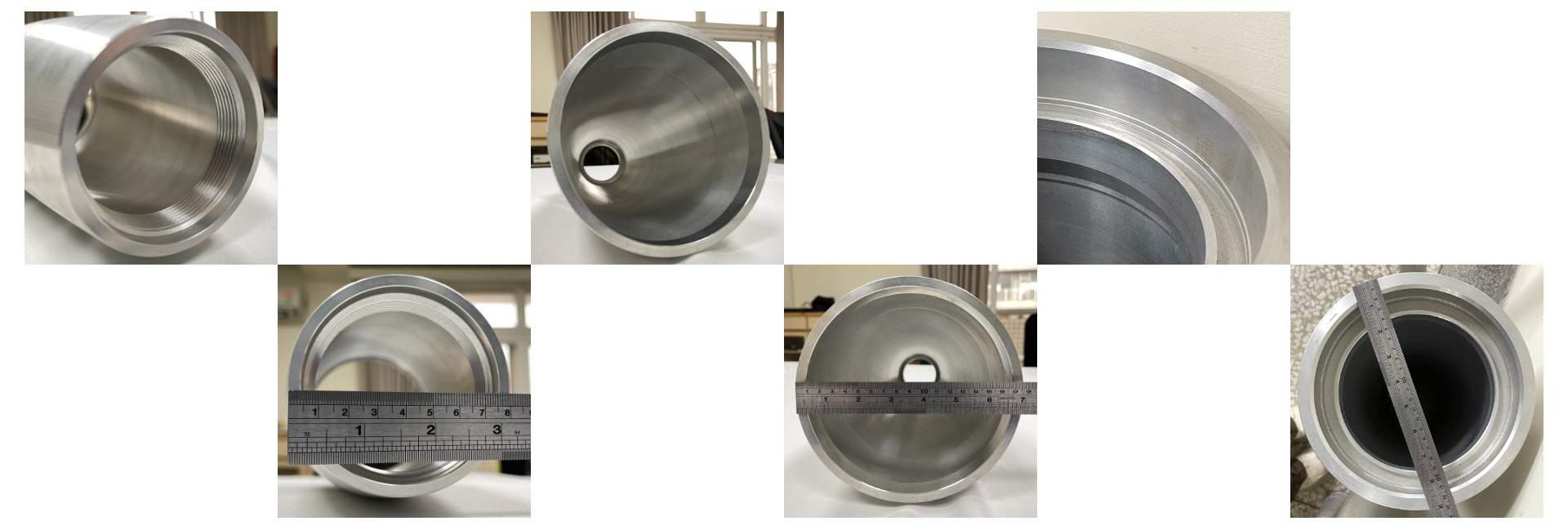

Special Aluminum Tube

Large Diameter Aluminum Tube Processing

Length: According to the drawing standard

Material: 7 series / 6 series / 2 series aluminum alloy

Application: All aluminum alloy tubes

Advantages: suction tube processing and forming, higher strength

Stress Test: ASTM Tensile Test

Custom Seamless Tubes

Elliptical tubes, seamless aluminum round tubes, aluminum square tubes, aluminum rectangular tubes, aluminum seamless specialty tubes, special aluminum extruded profiles, etc.